In this article, we will revisit the topic of brake dust, and look at some of the devices that are in the public domain that hope to solve the issue. We will see growing evidence of testing activities, as well as commercialising new concepts, and review the surge in new intellectual property in this area.

You can’t control what you can’t measure.

First stop on this journey is a quick review of the civic and legal context for this. We know that much attention is paid to vehicle emissions, and we also know that stringent efforts are being made to clean up air quality, including the contribution from road transport. When we considered the effect of lockdown in 2020, we saw a widespread and sustained push towards mitigating and reducing various pollutants, including the particulate matter that concern us with brake dust.

This knowledge is not lost on government bodies. Indeed, within Europe and the USA, brake emissions have been understood to play a significant role in air quality. So it should come as no surprise that coordinated international efforts are underway to agree a method of measuring and eventually mitigating these emissions. For the European Union, a working group consisting of vehicle manufacturers, suppliers and academics are working with the scientific arm of the European Commission, the Joint Research Centre to reach a consensus on both laboratory methods and a suitable test cycle to measure brake particles. Japanese and US legislators are included as well, with the Japanese in particular taking an active role in verifying the approaches for their jurisdiction. These efforts are expected to conclude in 2020, and therefore the next stage for the industry will be how to manage brake emissions.

Time to get the lead out

So it follows that the brake industry is engaged in finding strategies to limit emissions. Recent spy shots have shown some active test programs at major OEMs, and the major industry conferences are chock full of brake emissions papers, presentations, workshops and product booths. And in the midst of this several companies have created propositions to capture brake dust as it is generated, either through filtration enveloping the brake disc, a remote vacuum pulling dust to a central filter, or through a sealed encapsulation device which surrounds the brake completely.

The first of these is from a company called Clean Brake Performance. This system is designed to sit alongside the calliper, and so fully encompass the disc. It uses the pumping effect of disc vanes to force air through filtration elements aligned to the friction surface. As such, it is functional as long as the vehicle is moving, and can prevent emissions which occur between brake events.

Fig. 1: Clean Brake Performance utilise air flow through disc vents

Next is a company called Tallano, with their Tamic product. This system uses a remote vacuum and filter, with a novel design of pad to ensure generated particles are captured. The system incorporates an electronic controller, and can be triggered by a suitable brake request to begin filtration. The reliance on a remote vacuum, rather than disc-based pumping means there is no loss of thermal capacity in the disc, and the system can operate equally well at any vehicle speed. However, in order to capture dust, the pad must be engaged at the friction surface. Therefore, it is likely that any off-brake emissions may not be captured.

Fig. 2: Tallano’s suction system on a pad seeks to capture debris as it’s created

Next on our list is an established automotive filtration company, Mann + Hummel. They have brought their filter design experience to bear into the brakes industry, and developed a system to capture particles at the disc. The filter is placed next to the calliper, and partially envelopes the disc surface. The design filters primarily in an axial direction, but has filtration on a radial outlet which would align to a cooling channel.

Fig. 3: A view of Mann + Hummel’s brake filter layout

The three approaches above claim up to 90% of emissions can be saved. But as we discussed earlier, there isn’t (yet) an agreed method of measuring emissions, so one person’s 90% could be another person’s 50%. Filtration relies on capturing and entraining the airflow from the friction surfaces. Airflow within a braking system is a complicated subject, and its constantly in flux. Factors such as air temperature, humidity and local road conditions can change the flow dynamics reaching a disc. Indeed, with reference to the JRC work above, an agreed approach on air flow within a dyno setup has proved one of the most difficult aspects to agree and establish.

Fig. 4: Terra Dura Concept

Another approach is to encapsulate the foundation brake completely, and therefore prevent all possible emissions. This approach has been adopted by Advanced Braking Technology, with their Terra Dura product. Terra Dura is already a proven technology used within the mining industry and was created to protect the brake from harsh environments, however the implications for normal environments mean the protection elements can be used to completely eliminate brake emissions in any driving conditions. This has the dual advantage of protecting the friction surfaces from unwanted environmental inputs, while keeping emissions safely controlled until service. Advanced Braking Technology is currently exploring the use of Terra Dura across a number of emissions free braking applications.

Blank sheets of paper

Looking behind the innovation curtain of some of the major OEMs can also give some insights. Firstly, if we look at how many patents are being registered in the area of brake emission controls, we can see a sharp increase in the last 5 years, which coincides with the topic gaining interest at conferences and from legislators. While the topic had registered less than 5 entries a year for most of the 21st century, in recent years, there has been a marked increase in IP generated. Some of these are clustered around the commercial developments noted above, but many others come from major OEMs looking to find a palatable solution to brake dust emissions.

Let’s have a look in detail at a few of the more interesting. BMW have registered a number of patents around an idea of a filter system attached to each brake calliper, with an air channel to move the dust towards the filter. The filter may include increasingly finer filtration, where larger particles could be released and finer particles captured, or the filter may regenerate when full.

Fig. 5 – Three views of BMW filtration system proposal, including normal operation and regeneration modes.

Both Bosch and Continental have been researching their own solutions, which seem to reference their experience on exhaust gas emissions.

Fig. 6: Bosch’s proposed particle capture device, with associated circuit diagram

For Bosch, the proposed solution encompasses a device located next to the calliper, which receives dust based on brake disc rotation. The device encompasses an adhesive surface to trap the dust, which is connected to a high voltage source, thereby (it’s claimed) increasing the effectiveness of the filter.

Fig. 7: Continental’s air guide design, with throttle flap and filter element

Continental have taken a twist on a familiar theme, using a variety of novel airflow management techniques to capture dust in an airstream and direct it to either a dedicated filter downstream from the friction pair, or entrain the airstream into exhaust flow, and deal with these particles using existing exhaust filters.

Fig. 8: Continental’s novel exhaust repurposing

Moving back to OEMs, Ford have been particularly busy, with a wide variety of approaches, from simple slots on the disc outer edge to move dust off the friction surface, to a magnetized plate within a dust collector, to attract metallic dust particles. In this scenario, an electric charge is passed through the plate when braking is engaged, to create a suitable magnetic field. Another idea integrates water management in a vehicle to be used in a wide variety of systems, including tyres and brake pads to control particulate emissions. But Ford have gone further than others, even registering a device to measure brake emissions on a road vehicle. This suggests a deep level of research underway at Ford, and corresponds with the fact that Ford participants have been involved with the JRC Working Group on particulate measurement.

Fig. 9: Ford’s on-vehicle particulate measurement device, used to establish emissions in a vehicle context.

Hyundai have registered a number of patents aimed at reducing the visual problem of brake dust on wheel surfaces, while also limiting dust emissions overall. They rely on an absorbent material attached either to the calliper body or the pad backing plate. In each case, the spent pad material is captured onto the foundation brake hardware, to (presumably) be disposed of during a service intervention.

Fig. 10: Hyundai’s absorbent material (denoted 10 and 70), located within the calliper

Knorr have developed a number of concepts relevant for heavy vehicle braking, which rely on a remote filter and blower. Separate patents are filed for both drum and disc brakes, but the filtration system seems common to both. In the case of the drum brake, a clean air feed is also provided, such that a reasonable air flow can be created.

Fig. 11: Knorr’s truck brake solutions, utilising a remote blower and filter

The lions’ share of inventive efforts

Perhaps the most active inventors in this field is the French Group PSA, which include the famous historic brands Peugeot and Citroen, as well as recent additions DS Automobiles, Opel and Vauxhall. (Depending on when you read this, a proposed merger between Group PSA and Fiat Chrysler may have been completed, or completely abandoned).

Anyway, boardroom politics aside, the engineers have had a busy few years thinking up a variety of detailed approaches to brake dust. The catalogue is quite diverse, and includes ideas on pads, filters, airflow systems, as well as arrangements for discs and drums.

Fig. 12: PSA’s magnetic wheel spoke inserts (denoted 20), which can attract particles (30)

One idea that seems familiar to others mentioned above describes a magnetic addition to wheel spokes to capture metallic particles as they are ejected from the calliper.

Fig. 13: Airflow management concepts for drum and disc brakes

Two similar approaches to moving particles away from the point of creation, the engineers considered aerodynamic devices to encourage extraction of particles from the foundation brakes. Both concepts include a filtration element downstream of the foundation brake.

Fig. 14: A wet encapsulated brake system, to prevent brake emissions

A rather novel concept PSA created encapsulates a wet brake system within a sealed cavity, and pumps through a fluid to both manage thermal loads and prevent any brake emissions. The system includes a pump (40), a particle filter (42) and a fluid cooler.

Fig. 15: An air circulation system to manage brake dust around the pad

Next comes a detailed system to introduce airflow around the periphery of the pad, delivering clean air to the leading edge, and extracting dirty air through the trailing edge of the pad. Air is also pulled from the disc via cooling channels. A variation on the pad surrounding has also been registered, which separates the deflector from the pad back plate.

Fig. 16: Two methods of dust filtration from PSA

Finally, a couple of detailed approaches to a particulate filter were registered. One includes a filtration liquid, through which dirty air is bubbled, and cleaned by doing so. The other idea relies on centrifugal force. Both concepts compliment other approaches described above, where remote filtration is included.

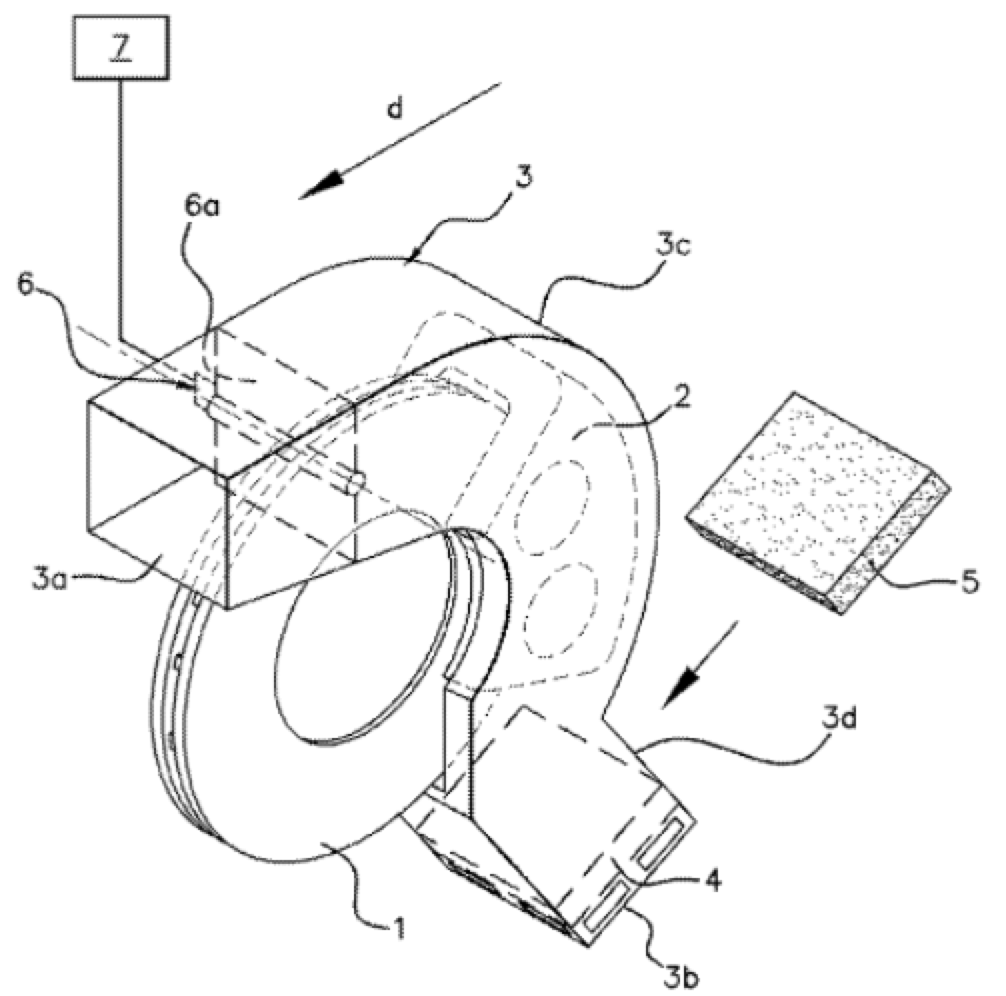

Fig. 17: Porsche’s encapsulation approach, with integrated filter and air flow management

Rounding out our review of brake emissions control innovations is an entry from Porsche. Here, the invention foresees a completely encapsulated disc, whereby a cover (item 6) works together with the calliper (item 2), and forces air flow through a filter element (item 9) which partially encircles the disc. This system looks similar to some other entries, but has distinct features regarding how the particles reach the filter element.

While this article contains a review of some of the more noteworthy ideas around brake emissions control, it’s by no means exhaustive. Searching through the patent catalogues can be revealing of a company’s approach to a particular topic, as well as how often these approaches can overlap. A few companies have clearly been more exercised than others, and some companies have clearly benefitted from their involvement in regulatory working groups.

As we narrow in on a comprehensive set of rules regarding brake emissions, I expect that the research and inventive activity in this area will continue to blossom, and we will begin to see more evidence of test programs examining some of the concepts above.